Mr. Ranjit Bose

Founder

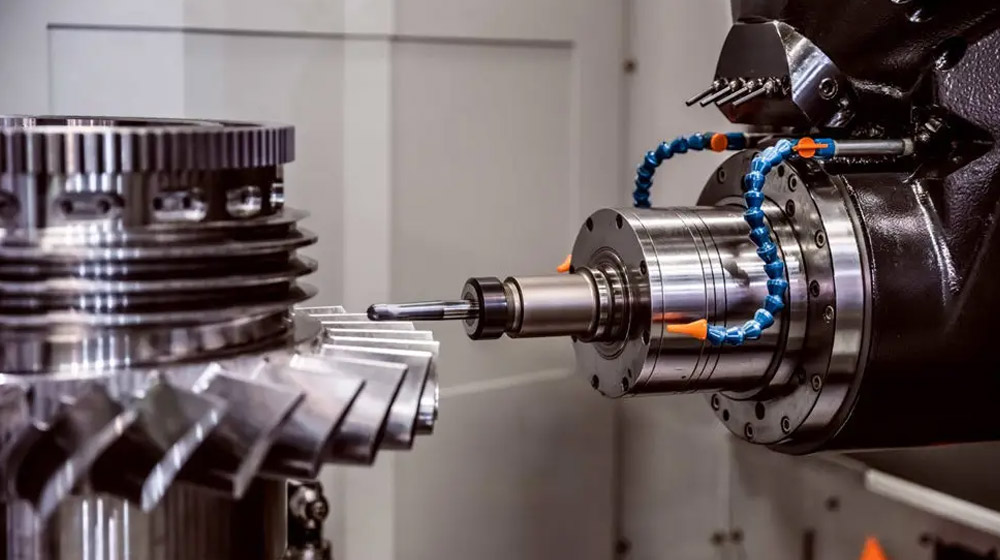

We are a precision engineering company specializing in forging dies and die regeneration, CNC machining, and robotic welding solutions.

At Carver Roboweld Ltd, we deliver precision-driven engineering solutions designed to meet the evolving needs of modern industry. Our core offerings include:

From tooling and machining to automated welding, we provide complete manufacturing support with a focus on quality, durability, and innovation.

We leverage cutting-edge technology to deliver unmatched precision, efficiency, and reliability across every stage of production. Our investment in advanced systems and smart automation enables us to meet the most demanding industrial standards.

We believe that great products are only part of the solution — exceptional customer support completes the experience. Our dedicated support team ensures clear communication, timely assistance, and reliable service at every stage of your project.

Our strength lies in our team of highly skilled and experienced engineers who drive every project with precision, innovation, and technical excellence.

We understand that time is critical in every industry. That’s why we are committed to delivering all projects on schedule — without compromising on quality.

Established in 2009, with a vision to redefine reliability in welding, Carver Roboweld LTD. is a trusted name in the manufacturing of welding electrodes and metal cord wires.

Our state-of-the-art manufacturing facility is strategically located on the Rajkot–Ahmedabad Highway in Gujarat, India — a prime industrial corridor that connects us seamlessly to major manufacturing hubs across the region.

Our founder Mr. Ranjit Bose is a seasoned engineer and visionary leader who saw potential in metal and in people. Today, we stand as an exhibit of his vision – bold and unstoppable.

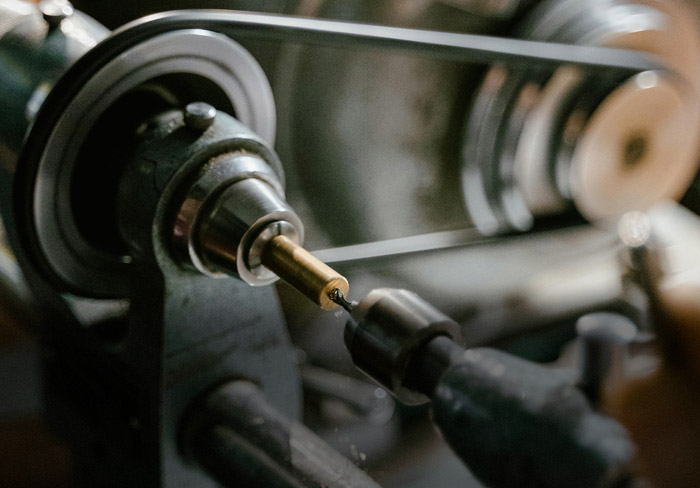

Forging dies are precision tools used in the forging process to shape metal under high pressure. They are critical in producing consistent and accurate components in industries like automotive, aerospace, and heavy machinery.

Die regeneration refers to the process of restoring worn or damaged forging dies to their original condition or extending their life through re-machining, welding, and heat treatment.

Regeneration is more cost-effective, faster, and environmentally friendly. It helps reduce downtime and extends the service life of existing dies, improving ROI.

The number of regenerations depends on the extent of wear, die material, and part complexity. Typically, a die can be regenerated 2–3 times, provided the core structure remains intact.

Common materials include H13 tool steel, tungsten carbide, and other high-performance alloys that can withstand extreme pressures and temperatures.

For any kind of query, contact us with the details below.

+91-281-2460531 & +91-281-2460532

302 – Om Com. Complex, 22-Bhaktinagar Station Plot, Tagore Road Corner, Rajkot – 360 002

Please feel free to Contact Us regarding any query pertaining to our products listed here. We will get back to you sooner than your expectations...!

We are a precision engineering company specializing in forging dies and die regeneration, CNC machining, and robotic welding solutions.

Educates advanced users about precision, complexity, and productivity.

Niche down into forging die applications and regeneration.

A comparison blog for plant managers and decision-makers.